Tumbled INK Fountain Pen

- Description

Description

2024 Re-launch

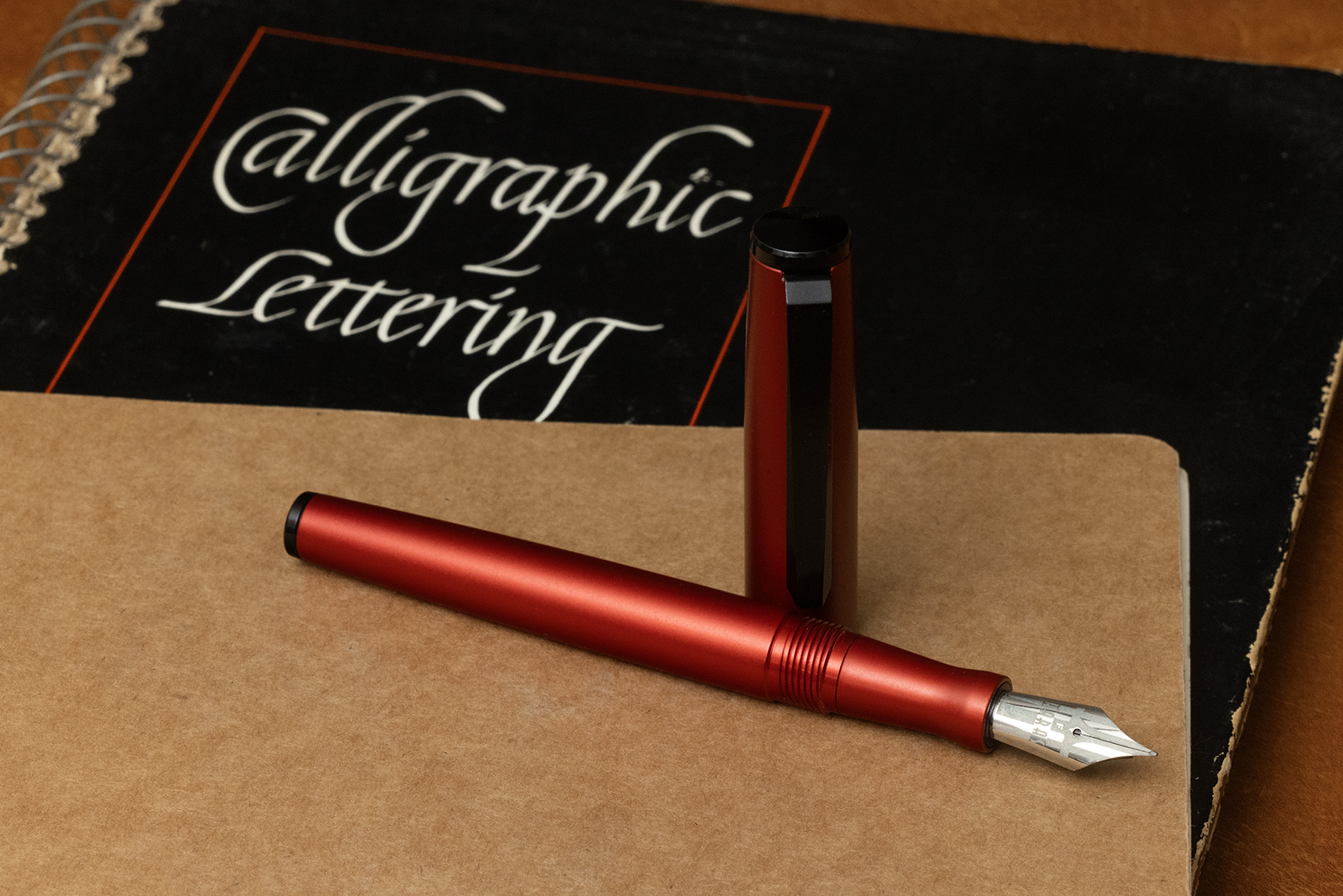

The INK, our flagship fountain pen, has gone through numerous iterations since it’s initial design in 2013, some things have remained the same. Pen reviewers used descriptions such as, “tank-like construction”, “ultimate pen”, “unique and stylish with just a hint of bad-ass”, and “an excellent addition to any writing arsenal”, and through all the engineering changes and adjustments, we managed to retain the elements that make up the core DNA of the INK. Some call it industrial and minimalist, which later became everyday carry (EDC) and indestructible; our mindset at the time was maximizing function and form on a machined fountain pen that “felt” like a Karas Kustoms product. The result was, and still is, a pen that really stands out. Even as fountain pens have exploded in popularity with thousands of new pens and pen designs hitting the market, the INK fits in an aesthetic and utilitarian category all it’s own.

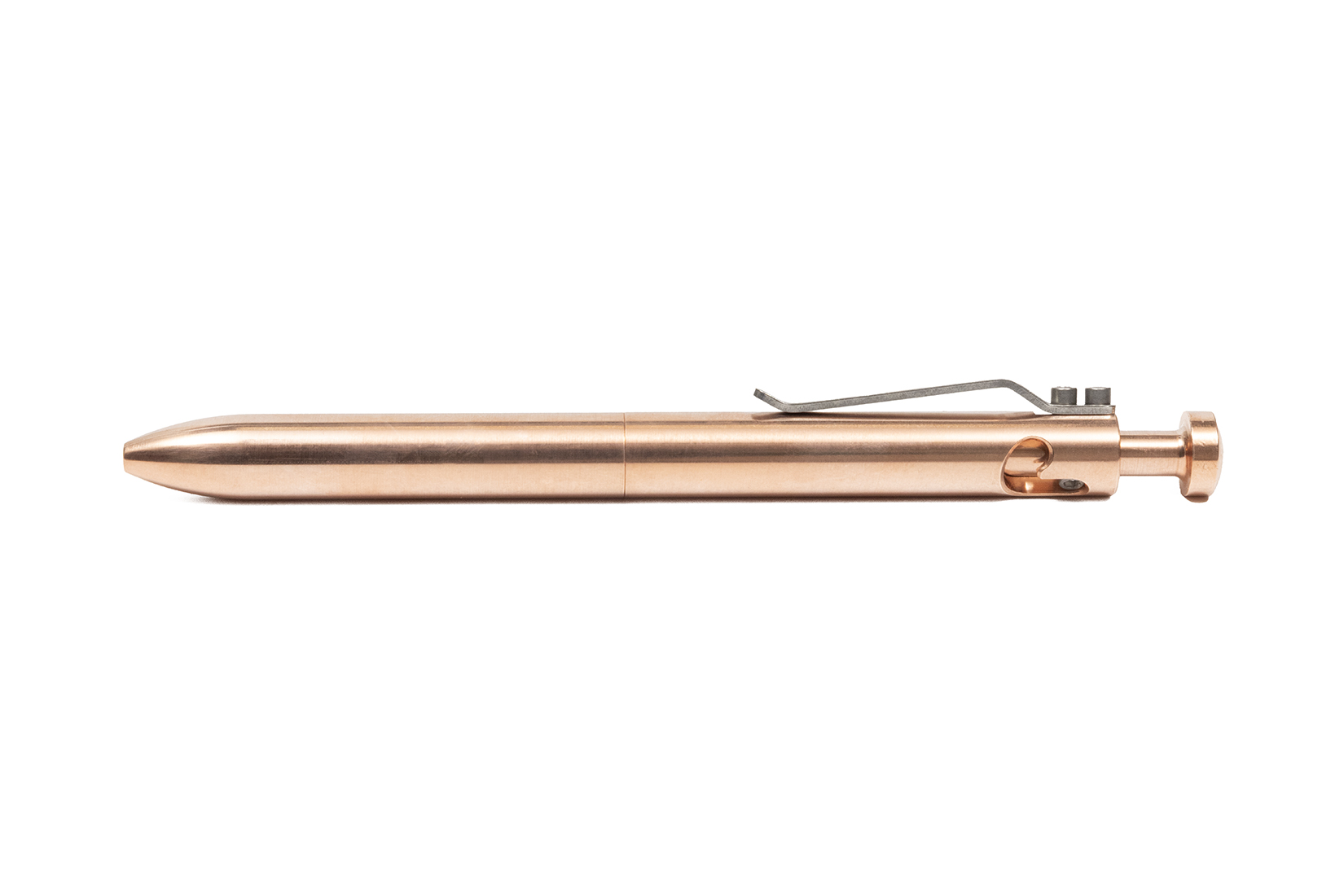

The latest revision of the INK fountain pen are relatively minor compared to some of the past updates. The main change is our official switch to milled aluminum clips, in matching anodize* for the aluminum pens. The tests are in, and the aluminum clips are fully functional and nearly as durable as our previous stainless steel clips. It is very unlikely they’ll break or fail during carry or use, though we do have a manufacturers warranty on all of our machined items. For the Brass and Copper versions, we’ve chosen Type III (Natural) anodized clips for extra durability but also the contrast in color is similar to the stainless steel look. Finally, all of the anodized versions have matching anodized Mk II grip sections available (IN LIMITED QUANTITIES). The Brass and Copper pens will also have the ability to purchase matching Mk II grip sections. Once these grips have sold out, we will officially phase out the Mk II (Frag) profile as an option on the INK. You’ll still be able to select the standard Black, Silver, Tumbled, Brass, and Copper grips if you prefer to have some contrast with your pen. The tumbled aluminum version uses a tumbled aluminum clip but does not have a Mk II grip section option. We are officially discontinuing the Silver anodized color on the INK as a body option due to low demand; it may come back once or twice a year as a special release, but for now it is not an option. Anodized aluminum options include the following gloss colors (bright dip): Black, Blue, Dark Green, Grey, Olive, Orange, and Red; and the matte color: Purple.

Specifications:

Capped Length – 137.82 mm / 5.42”

Uncapped Length – 126.32 mm / 4.97″

Maximum Body Width – 14.61 mm / 0.57”

Minimum Grip Width – 9.36 mm / 0.36”

Maximum Grip Width – 10.62 mm / 0.41”

Capped Aluminum Weight – 42.2g / 1.48 oz

Uncapped Aluminum Weight – 24.7g / 0.87 oz

Cap Does Not Post

The INK is made from 6061-T aluminum, C360 brass, and Tellurium Copper on our CNC lathes and Swiss machining centers, in Mesa, Arizona. Bock nibs are made in Germany. Schmidt converters are made in Germany. Monteverde inks are manufactured in Austria.

The INK is a full-sized, machined fountain pen that comes in aluminum, brass, and copper. The INK uses German-made Bock nib assemblies known for their quality and long life. Also included with each pen is a Schmidt K5 cartridge converter and 2 black Monteverde short international ink cartridges. The thread-on cap uses triple-start threads to securely attach itself to the pen and to allow the removal of the cap with only 1.5 revolutions. The new Sta-Fast cap features and internal silicone o-ring near the threads that seats on a machined flat just past the grip section, and provides a secure, tight fit that keeps the cap from coming unscrewed when pocket carried. We also test, smooth, and tune every nib before shipping your pen to ensure the nib is writing as it should. The nibs are tested using a K5 converter and our Karas Pen Co fountain pen ink which is made by Papier Plume. The cap does not post on the rear of the pen. Designed and manufactured in the USA.

*ANODIZE IS A PROTECTIVE OXIDE LAYER THAT IS DYED DURING THE PROCESS. DUE TO A VARIETY OF PHYSICAL AND CHEMICAL REASONS, COLORS MAY DIFFER SLIGHTLY ON PARTS AND MAY NOT MATCH 100% BETWEEN EACH INDIVIDUAL PART. COLORS IN PHOTOS WILL DIFFER FROM THE COLOR OF THE ITEM RECEIVED DUE TO BATCH-TO-BATCH VARIANCE. COLORS DISPLAYED ON EACH INDIVIDUAL MONITOR WILL ALSO VARY.