Ultem INK Rollerball Pen

- Description

Description

New INK Release

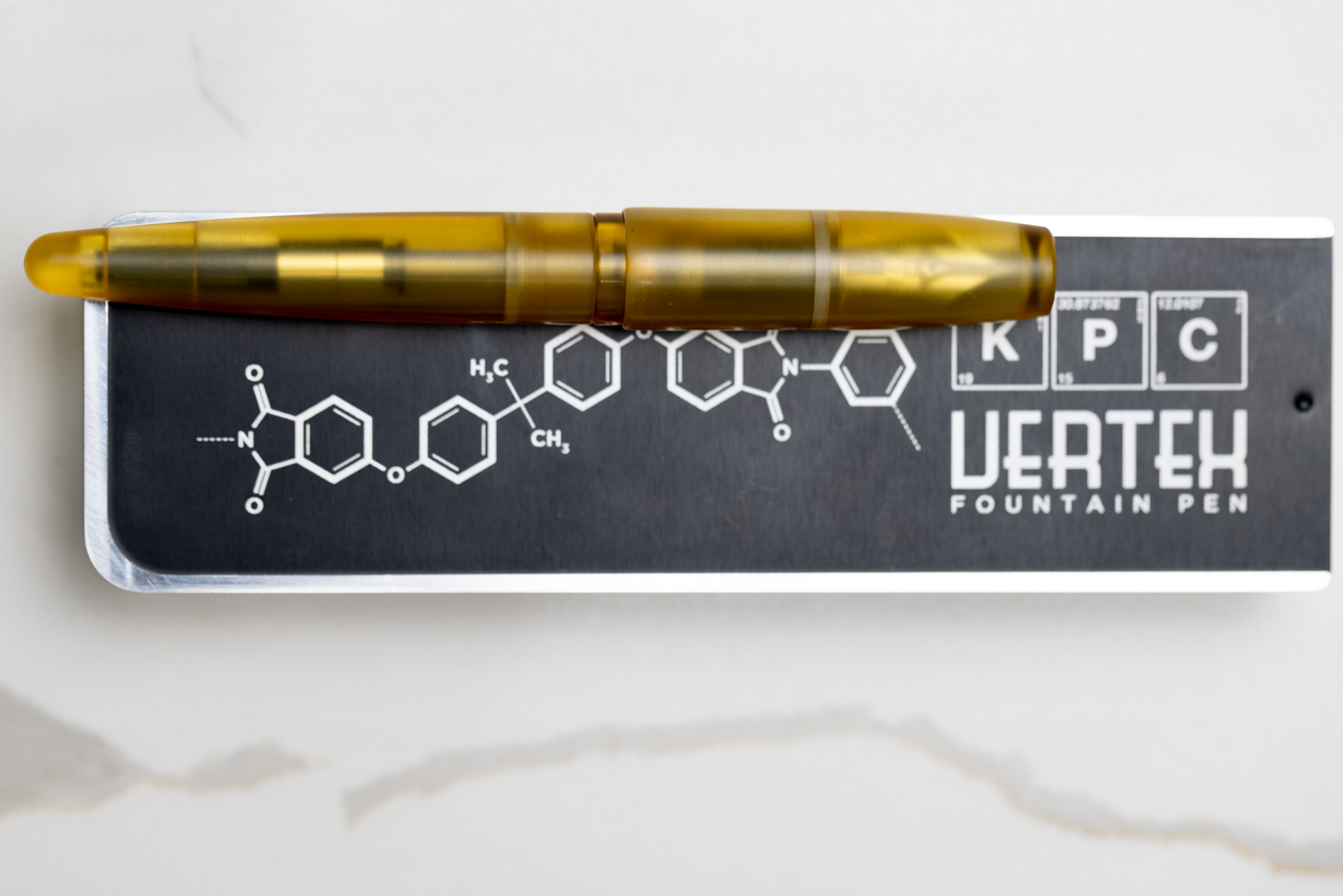

Polyetherimide (PEI), trade name Ultem, is an amorphous, amber-to-transparent thermoplastic with characteristics similar to the related plastic PEEK. Relative to PEEK, PEI is cheaper, but is lower in impact strength and usable temperature. Because of its adhesive properties and chemical stability it became a popular bed material for FFF 3D printers. Ultem is a family of PEI products manufactured by SABIC as a result of acquiring the General Electric Plastics Division in 2007, developed by Joseph G. Wirth in the early 1980s. Ultem resins are used in medical and chemical instrumentation due to their heat resistance, solvent resistance, and flame resistance. – source Wikipedia. We’ve been machining pens from industrial thermoplastics for quite some time. In fact, the first pen we released via Kickstarter had a very small run of Delrin (Polyoxymethylene) pens made for some very early backers. We’ve wanted to use thermoplastics and resins for the INK fountain pen not just because it’s our flagship fountain pen, but also because we think the unique design will benefit from having a wider array of aesthetic options. Once we sat down and looked at engineering tweaks for the clip and surrounding area on the cap, it didn’t take long for us to land on a few minor changes to make Ultem and other resins not just a possibility but a reality.

The Ultem INK is currently a special release pen fully machined from natural polyetherimide (Ultem). Natural Ultem is a nearly transparent amber (more on the yellow-amber side). Ultem is a “hard” plastic closer in composition to polycarbonate whereas Delrin is a “softer” plastic that has self-lubricating properties and somewhat of tackiness to its surface. Our Ultem Decograph is machined from solid PEI rod stock; bodies, caps, and grips. We’ve utilized several new machining techniques and custom tooling during the machining process to better ensure the transparency of the material is on display while minimizing tool marks. For this release, we’ve implemented a few new steps and modified some existing steps to the finishing process. The finished parts are hand sanded in a triple-step process, and then transferred to a tumbler with ceramic media that polishes the surface. This provides a semi-polished surface but does not cause the pens to be slippery like traditional polishing provides. The use of thermoplastics for the INK required changes to the cap manufacturing process to ensure we maximized the strength of the clip threading into the milled slot. In a traditional metal INK, the screws slide through the clip and thread into the posterior wall of the milled clip area. For the resin versions, the screw threads into the clip itself and into a guide hole on the posterior wall of the milled clip area. This provides as much strength as possible without changing the overall design of the pen. Select from either a Black clip or Grey clip when checking out to customize the look of your Ultem INK. When purchasing you will be prompted from a variety of rollerball tip options and refill options to customize your Ultem INK rollerball pen.

The INK is our full-sized, flagship machined fountain pen that intitally was made from aluminum, brass, and copper and is now being expanded to include a wide variety of thermoplastics and other resins. The grip sections are available in several finish and material options so you can customize your pen even more. The thread-on cap uses triple-start threads to securely attach itself to the pen and to allow the removal of the cap with only 1.5 revolutions. The thermoplastic and resin INK fountain pens do not utilize the Sta-Fast cap mechanism with internal o-ring due to the pen capping well and staying secure during pocket carry as well as the limited wall thickness for machining the o-ring groove. Each pen is designed and machined, by us, here in the USA. The INK was our first fountain pen, and remains the sole fountain pen in our original Kustoms Line of writing instruments.

The Ultem INK is designed and manufactured in Mesa, Arizona. Schmidt refills are manufactured in Germany. Pilot refills are manufactured in Japan.

Specifications

Capped Length – 137.82 mm / 5.42”

Uncapped Length – 126.32 mm / 4.97″

Maximum Body Width – 14.61 mm / 0.57”

Minimum Grip Width – 9.36 mm / 0.36”

Maximum Grip Width – 10.62 mm / 0.41”

Capped Ultem Weight – 22.7g / 0.80 oz

Uncapped Ultem Weight – 15.0g / 0.52 oz